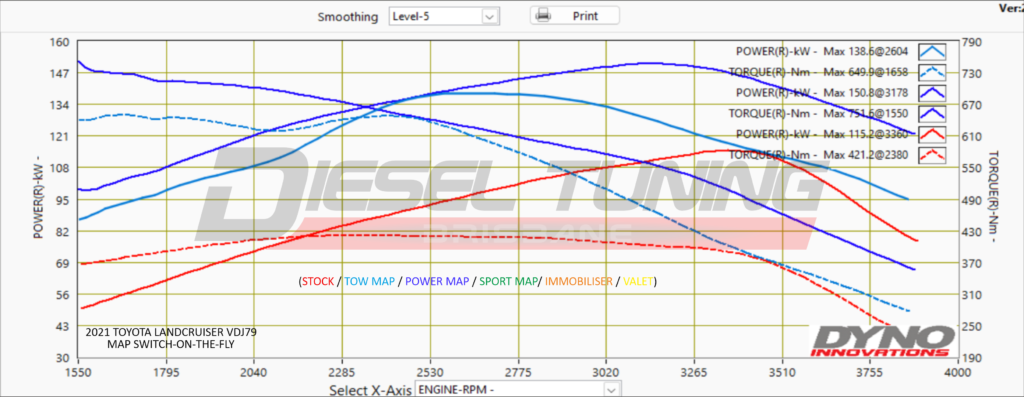

We’ve all marveled at the claimed horsepower of engines, only to learn that the stated power rarely reflects the actual might of the engine. Why the disparity? The answer lies in “corrected” horsepower values. These corrections were established to account for variations in observed horsepower readings due to different locations and weather conditions. It’s intuitive that an engine in The Snowy Mountains, won’t generate as much power as one at sea level in Brisbane due to the reduced oxygen at higher altitudes. However, the less obvious effects of weather conditions on the engine also play a crucial role. To level the playing field, advertised horsepower is “corrected” according to various industry standards.

Understanding Dyno Correction Factors

While many are familiar with Atmospheric Correction Factors used to compare power output across different days or locations, these factors can be perplexing and potentially misleading. Despite the tendency for engine owners to proclaim their horsepower as an absolute figure, we know that an engine will produce varying power on different days. To make fair comparisons, horsepower output on a given day is corrected to a standard.

Types of Dyno Correction Factors

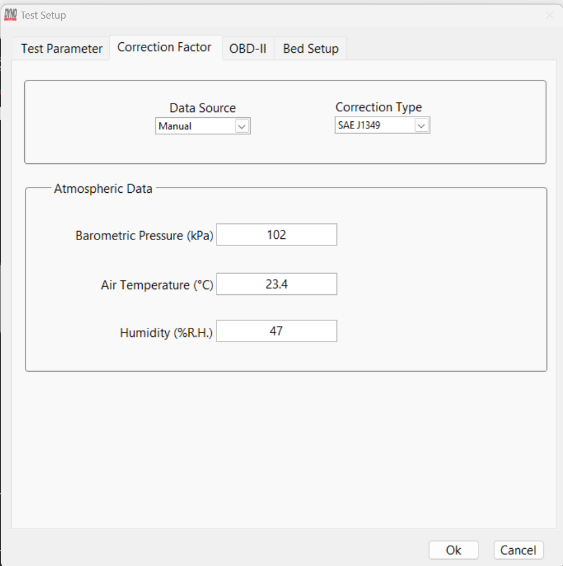

The most common correction standards include the SAE J607 (STD), SAE J1349, ECE, DIN, and JIS. These standards adjust for factors such as temperature, humidity, and barometric pressure. For instance, the SAE J1349 standard corrects to a 77°F day with 0% humidity and a barometric pressure of 29.234 in-Hg (99 KPa).

These corrections become crucial when comparing engine performance on different days. It is important to understand, these correction factors represent a theoretical value, not the actual value on the day, when takign into account the correction factor equation.

Read more: Understanding dyno graphs & how to catch a cheater!

Understanding SAE J1349 Correction

The most modern, and globally accepted correction formula is the SAE J1349, which involves the final correction factor multiplier (cf), pressure of dry air (Pd), and air temperature (Tc) in degrees Celsius. A point of confusion is the quoted values for Barometric Pressure in inches of Mercury, with variations based on temperature.

The SAE J1349 standard also accounts for “Mechanical Efficiency,” reflecting the engine’s energy conversion from fuel to flywheel power. This factor considers frictional torque, viscous effects, and other rotational resistances. The SAE flat rate of 15% efficiency is a point of contention, as it may not accurately cover all internal combustion engines. In particular, this should not be utilised for Diesel engines.

Read more: Correction factors in ECU software and their purpose

Dyno Correction For The Customer

While debates persist about the validity of correction factors, they remain essential for realistic engine performance comparisons on different days around the globe.

Entering accurate correction factor values is crucial for valid testing. While correction formulas may seem complex, most dyno modern software automates the process based on environmental variables. It’s important to use the same correction method for all testing, and transparency with customers regarding the correction method builds trust.

Conclusion

When considering a dyno, researching how correction factors are applied is essential. While it might not seem crucial now, the ability to enter custom correction factors may become vital for accurate testing and comparisons in the future.